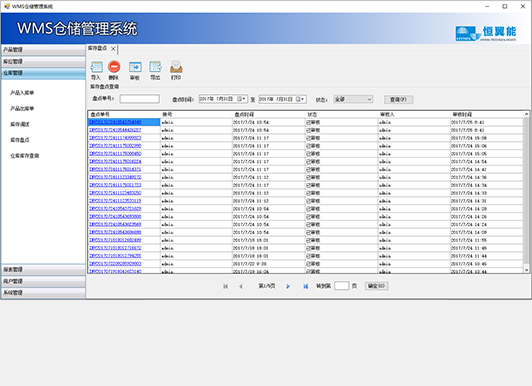

1. It allows query of the use status of the storage location, the record of product's storage and delivery, and occupancy of the inventory in real time, making it convenient to conduct tracking and management of products.

2. It can generate the warehouse data automatically, update the storage and delivery as well as inventory information immediately, thereby reducing error rate, time and labor cost.

3. Through the inventory, the data information concerning the actual inventory and book inventory can be accessible.

4. It is permitted to add and delete the system operator account. The powerful privilege control can limit the user's right to use the function in the system.

5. It is allowed to print and export the data information generated in the system in real time.

System structure

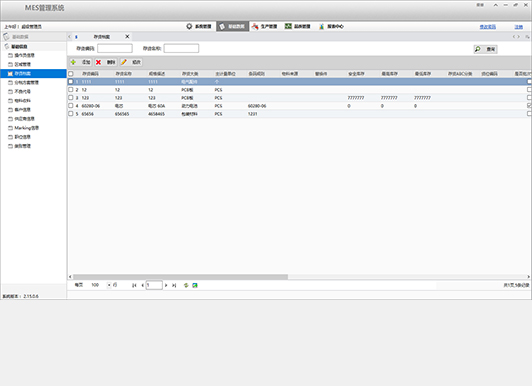

MES system

MES system

The MES System of HYNN can quickly and effectively realize real-time tracking and monitoring of production sites through the system's refined production scheduling, implementing production process monitoring, process route based production schedule management, and real-time information collection, analysis and feedback functions. It effectively solves the core issues in site management, and increases support for the site, thus creating a reliable manufacturing execution management system for the enterprise.

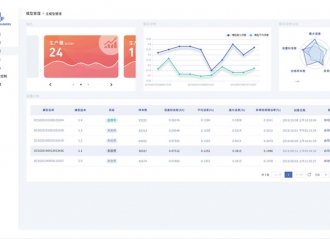

Capacity prediction system

Capacity prediction system

The system architecture introduces the real-time analysis architecture of cell data. It provides high performance computing architecture with flexible expansion, adaptive and low delay. It can analyze and calculate the characteristic data of the cell in real time.