Test items

Test the DC internal resistance of batteries.

System characteristics

1. The DCIR tester automatically tests the DC internal resistance of each single battery on the incoming battery tray, turns into a production management control system to automatically accomplish the binding of production data information and auto-saving, and transmits the data externally through network connections.

2. The DCIR tester, developed independently by our company which owns complete intellectual property rights, features high test precision, high reliability and stability, and can integrate seamlessly with automatic logistics equipment and technological equipment for the prior and next processes.

3. Embedded design is employed for the human-machine interface; the height of the display and operating platform meets the ergonomics requirements; the machine, featuring self-testing software and database system is easy to operate, reliable and stable.

Functional characteristics

1. Based on the principle of BSEN61960, the evaluation method of DCIR adopts the two-stage load current test and calculates the DCIR value based on the voltage difference caused by the current change, which is closer to the actual resistance effect of continuous battery current application. Therefore, power battery or high-power energy type battery can be evaluated for the DCIR characteristics.

2. The power cabinet tester, with the switching response time shorter less than 15ms and pulse width shorter than 100 ms, can instantly capture small change curve of current and voltage, providing an accurate and high precision test hardware platform for testing the DCIR of batteries. The software algorithm, developed in accordance with the HPPC standard test method, is approximate to the performance characteristics of the battery itself.

3. Due to the use of an alloy probe as the contact probe, the contact impedance is less than one half of that for similar probe of beryllium copper. In high temperature environment of 45℃, the overflow temperature rise for large current is less than 6℃.

4. Conduct shock test on battery with large current, calculate the DC internal resistance by dividing the voltage difference by the current difference, and the DCIR tester can screen out some batteries with damaged diaphragms in advance.

Test method

A. DC internal resistance in discharging

a1. 80A constant current, discharge for 10s [take voltage Vd0 in the 9thsecond].

a2. 150A constant current, discharge for 10s [take voltage Vd1 in the 1stsecond].

Stabilize for 20s.

B. DC resistance in charging

a1. 80A constant current, charging for 10s [take voltage Vc0 in the 9thsecond].

a2. 150A constant current, charging 10s [take voltage Vc1 in the 1stsecond].

Stop.

Equipment parameters

S/N | Content | Specification | |

1 | Voltage | Measurement and control precision of voltage | ± (0.05% FS+0.05%ST) |

2 | Measurement range (mV) | 0~5000 | |

3 | Current | Test precision | ± (0.05% FS+0.05%ST) |

4 | Measurement range (mV) | 0~300,000 | |

5 | Test procedure | Flexible settings according to requirements | |

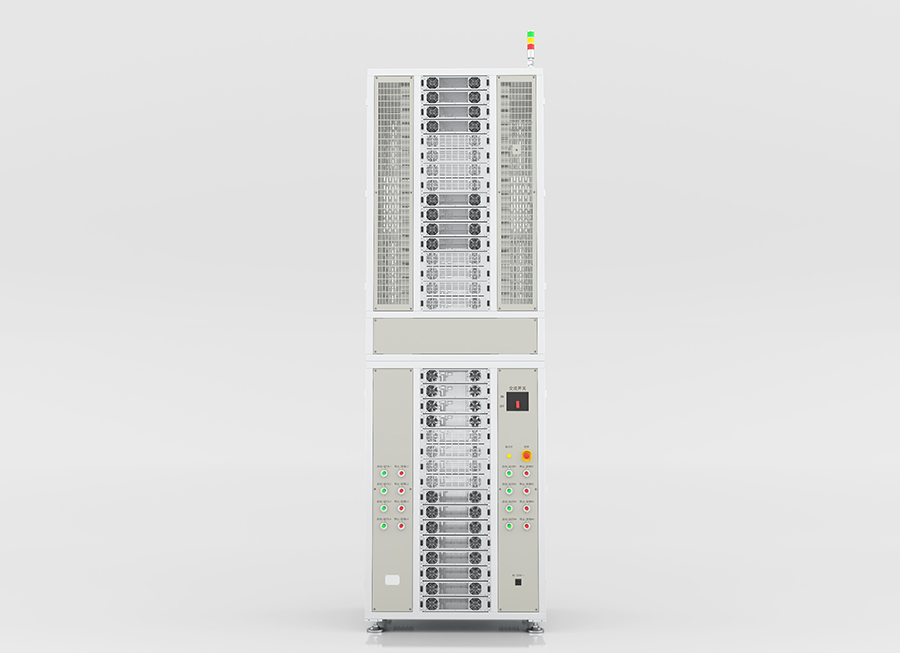

5V power supply cabinet

5V power supply cabinet

HYNN power battery testing system is mainly designed for power battery. Designed with high accuracy, high flexibility and high performance, it can meet all test requirements for battery with the range of 0-5V (Voltage), 20mA-30A-400A (Current).

Model:DECT0530A, DECT0560A, DECT05100A, DECT05200A, DECT05400A

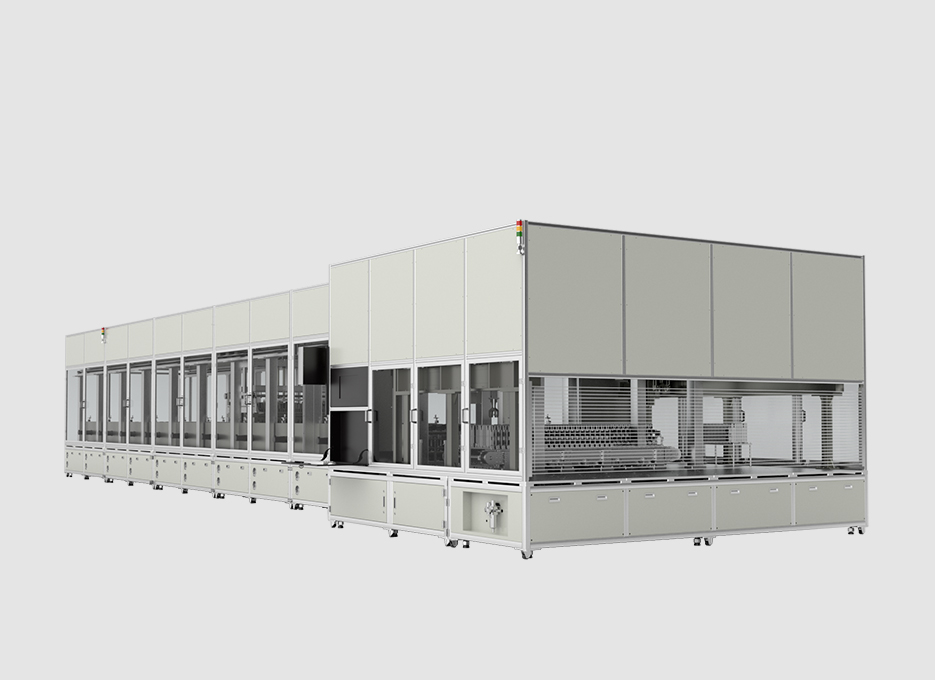

High-temperature pressure forming equipment

High-temperature pressure forming equipment

At present, a heating clamp is used to press the two sides of the battery during the production process of soft package batteries. The gas during the formation can be discharged into the airbag under the pressure, so that the electrolyte can be fully infiltrated and form a good SEI film during the formation of the battery cells.

Capacity-grading press equipment

Capacity-grading press equipment

HYNN press machine can complete the once-off crimping test for the entire battery panel and improve production efficiency. After the test is completed, it can automatically cut off the work step process, upload the test data and connect with the front and back processes seamlessly to realize data interaction.

OCV test equipment for pouch battery

OCV test equipment for pouch battery

HYNN OCV tester can automatically test for the open circuit voltage, AC internal resistance and shell cover insulation (the voltage between the positive electrode and shell) of the single cell in the battery tray. OCV testing is the essential process of battery manufacturing. Combining battery testing with battery tray for batch testing or single testing, it can reach to fast and reliable testing results. The production management and control system automatically calculates the K value according to the test data, and automatically completes the binding of the production data information, automatic saving and binding information. Data can be export through internet connection.

Pouch battery classification machine

Pouch battery classification machine

HYNN battery level grading machine automatically scans barcode for the incoming battery, selecting and grading finished batteries according to some set rules. The user can set rules and numbers of levels for grading. Programming is proceed via data of battery manufacturing process. The formation management control system can automatically grade and upload grading results data according to data from former process. The grading machine can perfectly connect with the automatic logistics equipment and process equipment.