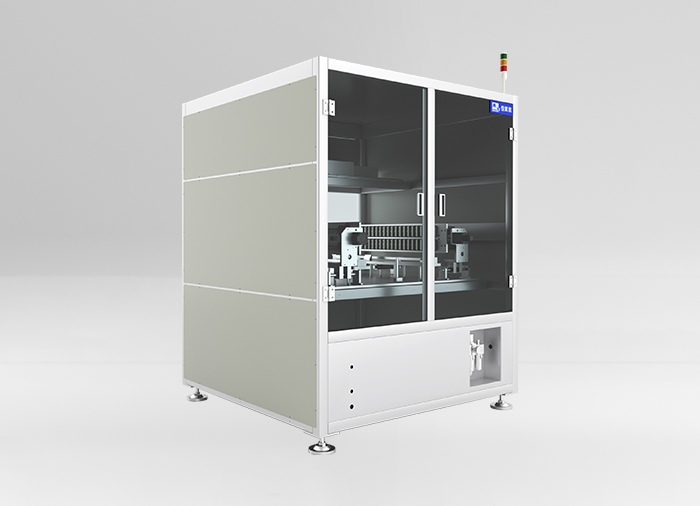

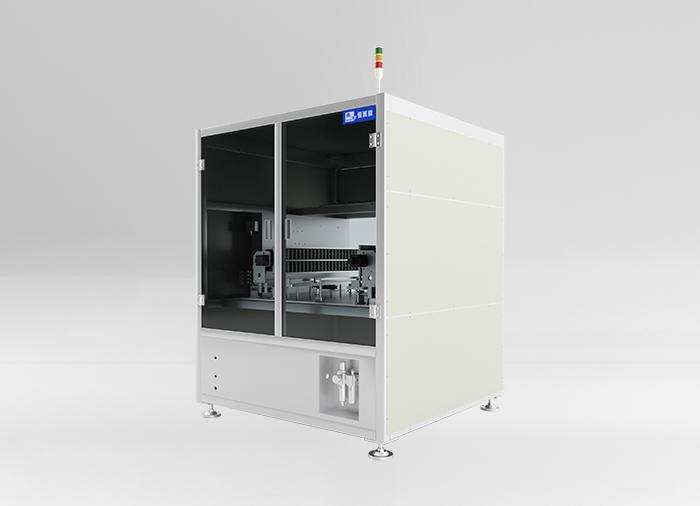

Test items

1. Test of the battery open circuit voltage (OCV).

2. Test of the battery AC internal resistance (ACR).

3. Case voltage test.

System characteristics

1. The equipment can be made on demand flexibly matched outside the output line orbridged inside the output line.

2. Embedded design is applied to the man-machine interface. The display height and operation platform are designed in accordance with the requirement of ergonomics.

3. High precision testing instrument is employed, which ensures a high precision as well as a stable and reliable performance.

4. OCV test device, with the independent research and development of intellectual property rights, can be seamlessly connected with automatic logistics equipment and process equipment in the last and nest procedures, which guarantees a high precision as well as a stable and reliable performance.

Functional characteristics

1. The internal resistance and open circuit voltage are tested independently with respective instruments. 34461A 6.5-bit meter is employed for voltage test, which ensures a high precision as well as a stable performance, while HIOKI 3562 meter is used for the internal resistance test, with the test resolution as high as 0.0001mΩ.

2. The probe cables of the battery test, intertwined with magnetic separation paper, are connected to the test instrument after being sheathed with stainless steel sealing trough, to avoid magnetic interference in the OCV test result.

3. The OCV auto-zero calibration function: The automatic zero fixture allows the cycle self-defining to achieve automatic zero calibration of the instrument of the open circuit voltage and AC internal resistance acquisition, which can substantially lower the impact of system test on the production and guarantee the trace of testing precision. The data will be automatically uploaded and kept in the management control system after the test.

4. It has the functions of testing the charged battery shell, picking out and removing bad OCV non-performing quantity.

Equipment parameters

S/N | Content | Specification |

1 | Equipment power | 2KW |

2 | Voltage test range | 0~6V |

3 | Voltage test range | 0.01mΩ~3.1000Ω |

4 | Internal resistance test range | ±0.01%rdg.±3dgt (V) |

5 | Voltage test accuracy | ±0.5%rdg.±10dgt |

6 | Test instrument | Agilent 34461A (voltage), HIOKI 3562 (internal resistance) |

7 | Applicable power supply | AC 220V 3¢ 50Hz |

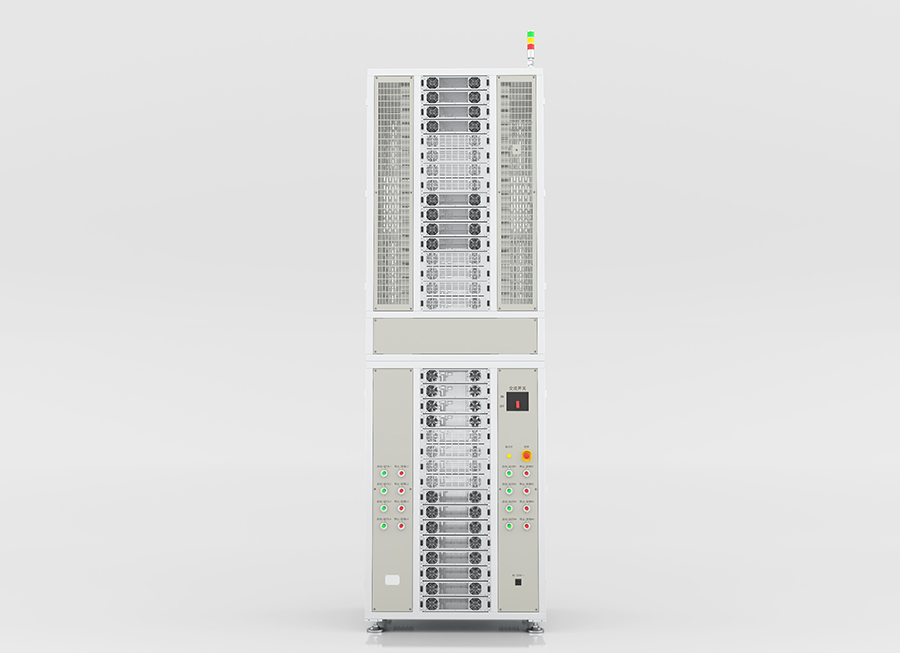

5V power supply cabinet

5V power supply cabinet

HYNN power battery testing system is mainly designed for power battery. Designed with high accuracy, high flexibility and high performance, it can meet all test requirements for battery with the range of 0-5V (Voltage), 20mA-30A-400A (Current).

Model:DECT0530A, DECT0560A, DECT05100A, DECT05200A, DECT05400A

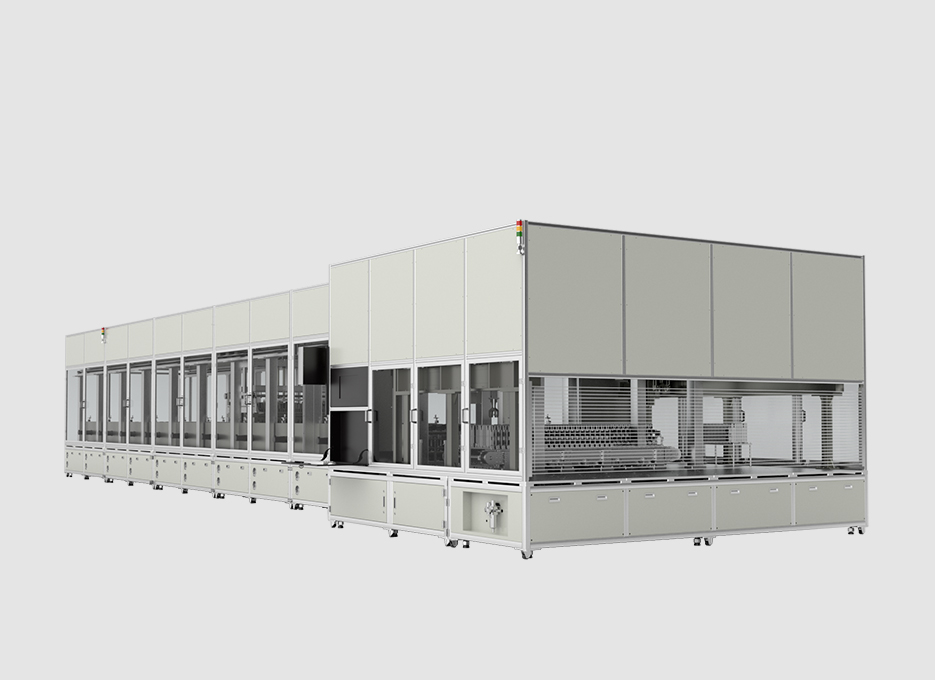

High-temperature pressure forming equipment

High-temperature pressure forming equipment

At present, a heating clamp is used to press the two sides of the battery during the production process of soft package batteries. The gas during the formation can be discharged into the airbag under the pressure, so that the electrolyte can be fully infiltrated and form a good SEI film during the formation of the battery cells.

Capacity-grading press equipment

Capacity-grading press equipment

HYNN press machine can complete the once-off crimping test for the entire battery panel and improve production efficiency. After the test is completed, it can automatically cut off the work step process, upload the test data and connect with the front and back processes seamlessly to realize data interaction.

DCIR tester for pouch battery

DCIR tester for pouch battery

Through the integration of PC computer, PLC and hardware, HYNN DCIR tester can accurately measure the DC internal resistance and open circuit voltage, realizing the perfect combination with the automation. The DCIR tester can not only test for the important parameters of battery measurement, but also fulfill the development of industrial automation and technology.

Pouch battery classification machine

Pouch battery classification machine

HYNN battery level grading machine automatically scans barcode for the incoming battery, selecting and grading finished batteries according to some set rules. The user can set rules and numbers of levels for grading. Programming is proceed via data of battery manufacturing process. The formation management control system can automatically grade and upload grading results data according to data from former process. The grading machine can perfectly connect with the automatic logistics equipment and process equipment.