System Characteristics

1. It can be integrated into the production line, matched with the production takt, and also be individually detected.

8. The multi-privilege management function facilitates the use management and security of system equipment, and different levels of authority can be assigned according to different operators.

Note: Please call for more test content.

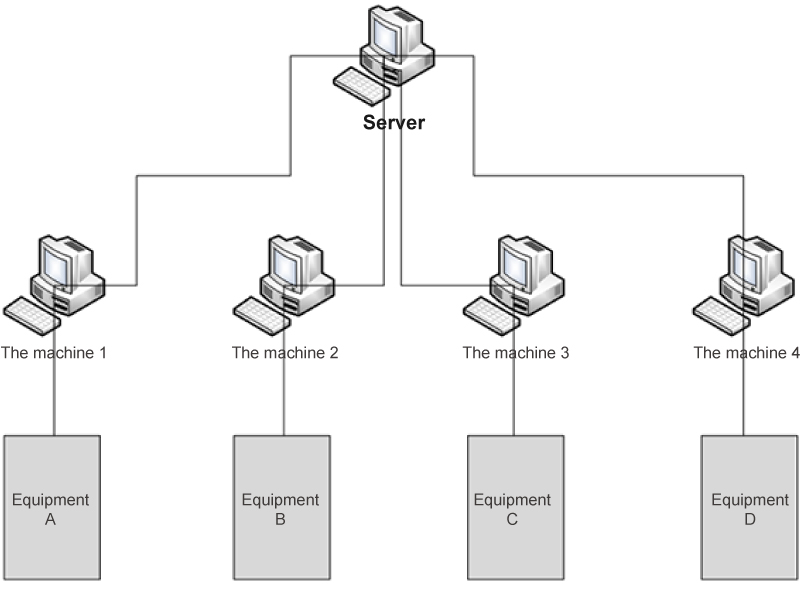

System composition

Equipment parameters

S/N | Items | Parameter |

1 | Equipment input voltage | 380VAC±10% three-phase and five-wire system, frequency 50Hz±5Hz |

2 | Power factor | >0.99 (rated power) |

3 | Efficiency | >92% (rated power) |

4 | Energy feedback | Current harmonics THD<5%, Power>rated power 50%, Feedback efficiency>85% |

5 | Output DC voltage accuracy | ± (0.05%FS+0.05%RD) |

6 | Output DC voltage accuracy | ± (0.05%FS+0.05%RD) |

7 | Current rising/falling response (battery) | 10ms, The current output is from 0 to the set value with no overshoot |

8 | Main channel data acquisition cycle | 10ms |

9 | Upper computer data record cycle | 10ms, it can be set by the customer |

Test system on battery cells

Test system on battery cells

HYNN power battery testing system is mainly designed for power battery. Designed with high accuracy, high flexibility and high performance, it can meet all test requirements for battery with the range of 0-5V (Voltage), 20mA-30A-2000A (Current).

Model:ECT0530A、ECT0560A、ECT05100A、ECT05200A、ECT05400A、ECT05800A、ECT051000A、ECT052000A

Module test system

Module test system

HYNN pack testing system integrates pack EOL equipment with energy saving equipment, of high compatibility, reliability and stability.The data acquisition system collects data for voltage and temperature of single battery module, as well as the total current and total voltage. The collected data is stored at a special database and the system proceeds data statistics, analysis and report generation.To provide effective test data and accurate performance parameters for battery module product offline detection, and simultaneously to determine whether the module is qualified for production. To provide test basis for the effective management of battery modules assembled into PACK.Test data can be uploaded to the factory MES system.