Test items

1. Conditional classification of open circuit voltage of battery.

2. Conditional classification of battery discharging capacity.

3. Conditional classification of K value of battery.

4. Conditional classification of battery platform capacity.

5. Comprehensive classification of battery parameters.

6. Screening for elimination of NG defectives.

System characteristics

1. The equipment capacity can reach 100ppm, and the failure rate is less than 0.01. Multi-position design can be realized, and multiple grades can be customized and developed according to customer requirements.

2. The scan code mechanism can automatically scan the barcode for battery tray and the QR code for single-cell battery. If the scan code fails, the alarm is immediately notified and manual processing is reminded.

Functional characteristics

1. Alternate options of segment: customize voltage, AC internal resistance, DC internal resistance, K value, platform capacity, etc.

2. The jaws of grouping machine have the function of detecting the position of the battery clips, without battery catching, battery falling, etc. When an abnormal situation occurs, the equipment will automatically stop running and alarm, reminding the manual inspection processing.

3. The same type of products will be picked up by the equipment and placed on a new tray. The classification screen is reliable and easy. The automated machinery is selected to avoid human error.

Equipment parameters

S/N | Content | Specification |

1 | Supported battey type | Cylindrical bttery |

2 | Equipment power | 5KW |

3 | Grades | Customized according to the actual nedds of custormers |

4 | OperatinG temperature range | 0~40℃ |

5 | Operating humidity range | 0~85% |

6 | Applicable power supply | AC 220V 3¢ 50Hz |

7 | Air pressure | 0.5~0.85MPA |

8 | Input and output materials | The Tray automatically flows in. When finished, the empyt tran is automatically ejected |

9 | Equipment failure rate | 0.01% |

10 | Alternate options of segment | Customize voltage, AC internal resisitance, DC internal resistance, K value, capacite, etc. |

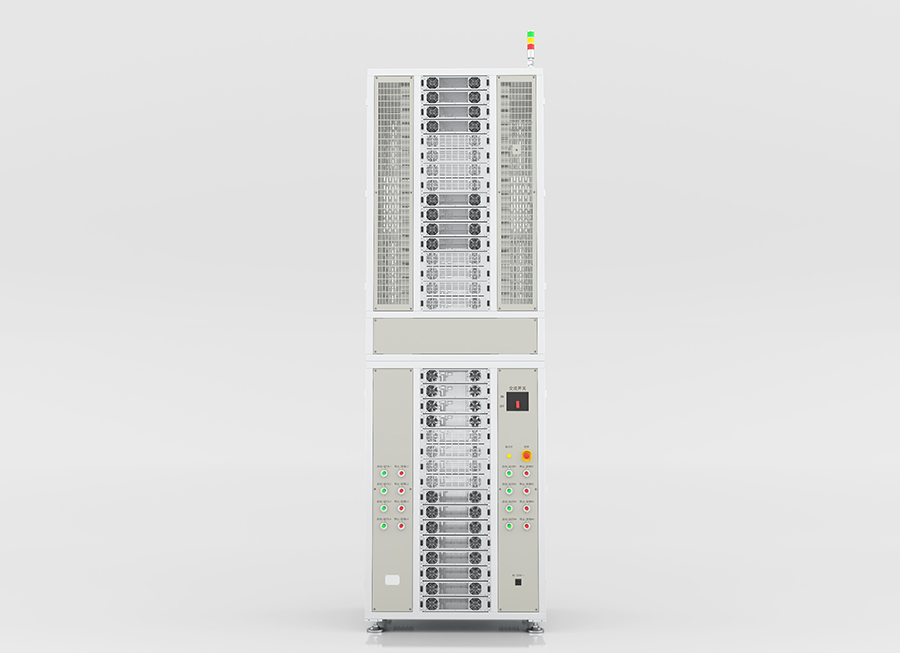

5V power supply cabinet

5V power supply cabinet

HYNN power battery testing system is mainly designed for power battery. Designed with high accuracy, high flexibility and high performance, it can meet all test requirements for battery with the range of 0-5V (Voltage), 20mA-30A-400A (Current).

Model:ECT0530A, ECT0560A, ECT05100A, ECT05200A, ECT05400A

Negative pressure formation needle bed

Negative pressure formation needle bed

HYNN negative pressure formation needle bed applies with six-sided protection scheme.Each storage position layer is isolated with stainless steel plate and fire proof rock wool; Needle bed is equipped with water fire protection and gas fire protection; Storage position is designed with smoke and temperature sensors. Safe and reliable, it is the most popular and advanced design scheme for ternary cells and lithium ferrum battery testing nowadays.

OCV test equipment for cylindrical battery

OCV test equipment for cylindrical battery

HYNN OCV tester can automatically test for the open circuit voltage, AC internal resistance and shell cover insulation (the voltage between the positive electrode and shell) of the single cell in the battery tray. OCV testing is the essential process of battery manufacturing. Combining battery testing with battery tray for batch testing or single testing, it can reach to fast and reliable testing results. The production management and control system automatically calculates the K value according to the test data, and automatically completes the binding of the production data information, automatic saving and binding information. Data can be export through internet connection.

Automated logistics line

Automated logistics line

Automatic warehouse logistics system has become an essential part of the logistics industry, along with the development of modern technology and production scale. The born of automatic warehouse logistics system has changed the development model of traditional logistics warehouse in work load and efficiency. So far, the system is widely used in the automatic production industry of lithium battery.

Automated warehousing

Automated warehousing

Automatic warehouse logistics system has become an essential part of the logistics industry, along with the development of modern technology and production scale. The born of automatic warehouse logistics system has changed the development model of traditional logistics warehouse in work load and efficiency. So far, the system is widely used in the automatic production industry of lithium battery.